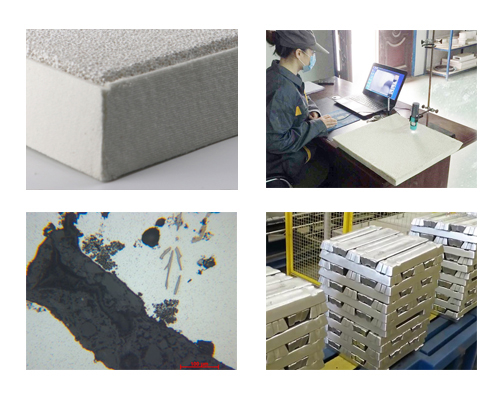

The ceramic foam molten Alu filters can effectively filter out the inclusions in the aluminum melt and the hydrogen adsorbed on the surface of the inclusions.

The material of the filter mainly includes corundum microporous ceramic tube, glass fiber mesh and foam ceramics.

The corundum microporous ceramic tube can filter out the oxide inclusions of several microns. The advantage is that it has a better slag removal effect, but the disadvantage is that it is low in efficiency.

The glass fiber net has strong adaptability, simple operation, and low cost. However, due to its small opening area, it is easy to block the gating system and the filtration is unstable. During use, the glass fiber mesh needs to be replaced frequently, and it is difficult to remove small-sized inclusions. The hole size of the glass fiber mesh is 1.2 mm×1.5 mm, the number of holes per square centimeter is 30, and the filtration flow rate is about 20 kg/min.

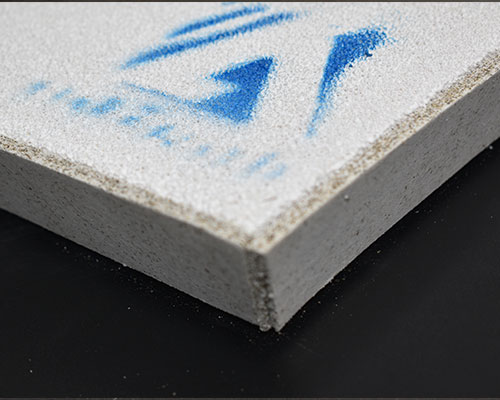

The ceramic foam molten Alu filters have high porosity, large adsorption area, and convenient operation. The ceramic foam filter has the best filtering effect on oxidized inclusions above 10um, but it is difficult to remove tiny-sized oxidized inclusions. In order to obtain high-quality aluminum melt, the smaller the pore size of the filter plate, the better. In practical applications, the CFF filtration method is often combined with the blowing method. Because ceramic foam is brittle, easily damaged, cannot be reused, and its pores are relatively straight, the removal efficiency of inclusions is low.

Tests have proved that the use of high-efficiency purification flux + CFF filtration process to purify the aluminum melt can reduce the impurity content and pinhole rate of pure aluminum by 70% to 82% and 60% to 88%, respectively. After online degassing, the performance of aluminum can be further improved. The key to flux filtration and purification is to complete the three processes of melting, degassing and impurity removal of aluminum at one time during the smelting process, which can significantly reduce defects caused by inclusions in aluminum.