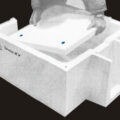

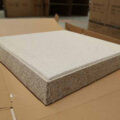

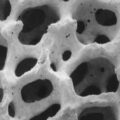

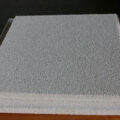

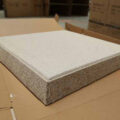

Aluminum foundries usually use ceramic foam filters in their filtration operations. Molten aluminium filter reduces the number of castings that must be scrapped due to the presence of impurities, thus improving the cleanliness of the castings. Generally, ceramic foam filters are incorporated into the casting operation upstream of the cavity. The ceramic filter can remove scum, slag and other impurities found in the molten metal before the casting operation. The most common types of ceramic foam filters include rigid honeycomb ceramic structures and rigid reticulated ceramic foams.

Aluminum or aluminum alloy ingots are melted through a melting step, and the aluminum base metal is molten aluminum; a holding step to maintain the obtained molten aluminum; a degassing step to remove hydrogen from molten aluminum; a filter to remove inclusions from molten aluminum; the casting step, the molten aluminum is poured into a water-cooled mold to solidify the molten aluminum into a predetermined shape.

In the production process, the base metal used to prepare aluminum from ingot aluminum, molten aluminum is heated to 700°C or higher. Since aluminum is a reactive metal, molten aluminum will react with air to form oxides.

In particular, in molten aluminum alloys containing magnesium (Mg), which is more active than aluminum, a large amount of oxides such as MgO, MgAl 2 O 4, etc. are generated and aggregated to form aggregates (dross). Since the dross is a very hard rock-like material, it will take a lot of time and effort to remove the dross. In addition, if the dross is partially collapsed and mixed into the aluminum ingot, it can cause surface defects and cracking of the end product (for example, aluminum flakes such as cans and disc materials).

In order to prevent surface defects and cracks of the final product and ensure the intended performance of the final product, various oxide removal processes are performed between the melting step and the casting step, and these processes include furnace refining. Online refining process and filtering process (executed immediately before the casting step). In particular, since the molten aluminium filter filtration process can remove even very fine oxides with a size of about 10 μm, the quality of the aluminum alloy can be ensured, which means that the quality of the final product can be ensured.