Molten aluminum casting process is the last process for aluminum alloy. Apart from the aluminum melting and refining process, it is an important step for obtaining high-quality aluminum alloy. After the degassing and filtering operation, the casting process is next.

Molten Aluminum Casting Process

Pull out the plug, use the preheated plug to clean the asbestos sleeve, asbestos rope, and other debris in the furnace eye, and then use the plug to open the furnace eye. If the furnace eye cannot be opened, a DC welder can be used. The furnace eye area is heated.

Put the refractory fiber cone on the plug head, put the plug head on the furnace eye in a balanced manner, adjust the flow of aluminum liquid by adjusting the plug head, so that the liquid level of the filter bag, tundish nozzle, and casting launder is stable, and the casting speed can be controlled at normal range.

As the production progresses, the flow of molten aluminum is gradually reduced. At this time, all the plug heads need to be pulled out, clean the asbestos sleeve, and put on a new asbestos sleeve.

After producing the junction, use a plug to clean the furnace eye, and put the plug head on the asbestos sleeve and insert it into the furnace eye to completely block the furnace eye.

The casting machine adopts a wheel belt continuous casting. Before casting, use sandpaper to polish the surface of the crystal wheel to remove oil stains and impurities. Place water-wiping cotton yarn and oily cotton yarn, and smooth the interface of the steel belt with a grinding wheel. The molten aluminum in the mixing furnace has a standing time and the temperature of the molten aluminum is between 730-750 degrees.

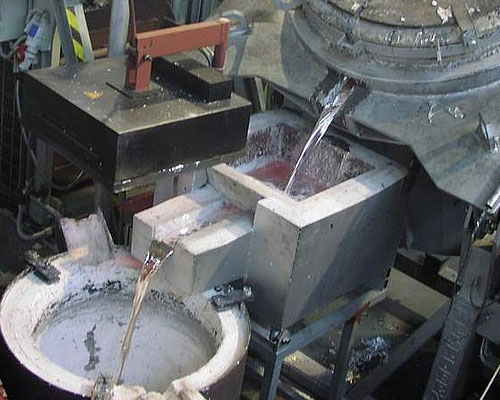

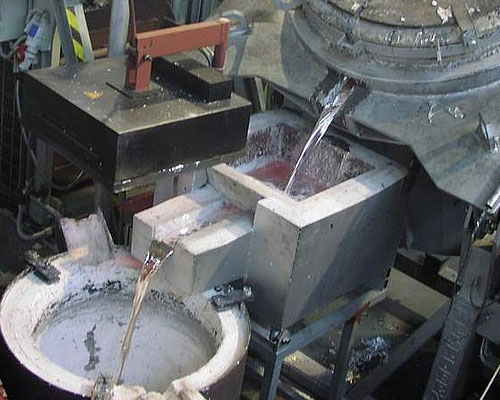

Open the furnace eye, the molten aluminum passes through the chute, the filter bag equipped with the filter plate, the tundish with the aluminum water diversion tube, and finally to the long launder, and the molten aluminum is put into the slag box.

When the temperature of the molten aluminum in the launder reaches 700℃ or higher, block the flow eye of the tundish and lift the long chute. Slowly adjust the float to make the molten aluminum enter the casting cavity of the crystal wheel stably. At this time, the casting machine is started slowly, and the liquid metal passes through the crystal wheel with grooves rotating. The crystal wheel solidifies the metal under the action of water cooling, and the crystal wheel continuously rotates.

For the cast billet with continuous solidification of the molten metal, after the casting is normal, a small amount of vegetable oil is added to the oily cotton yarn of the crystal wheel to ensure the smooth release of the cast billet. Adjust the casting speed to 7-11m/min, adjust the cooling water pressure to 0.01-0.40MPa, and the cooling water temperature below 40℃.

In normal casting, a special person is responsible for adjusting the balance of ladle shroud and float plate at any time, so that the liquid aluminum liquid is slowly and smoothly injected into the crystal wheel, and the cast blanks must not have flashing, hollow and other defects.