The structure requirements of the Molten Aluminum Feeding Nozzle are: when the liquid aluminum passes through the feeding nozzle, the streamline shall be reasonable without dead angle, the liquid aluminum shall be evenly distributed in the roll gap, the temperature of the outlet of the feeding nozzle along the cross-section shall be uniform, and the flow velocity of the metal at the outlet of the feeding nozzle shall be consistent.

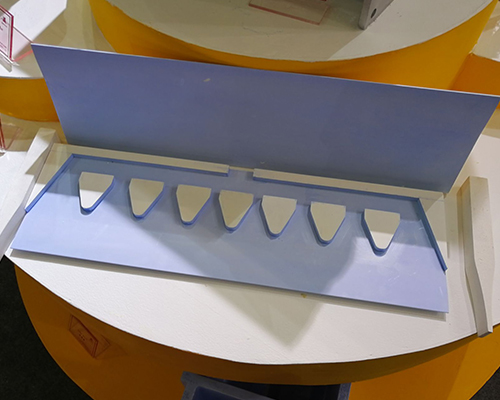

The Molten Aluminum Feeding Nozzle is composed of two upper and lower nozzles. There is a certain shape of splitter between the nozzles to ensure that the aluminum melt entering from the inlet can be evenly distributed to the whole inner cavity of the feeding nozzle. The flow of the melt in the feeding nozzle is generally affected by the relative position, structure size, number and size of the splitter. It can be selected according to its own process and equipment conditions.

The shape and size of the splitter block can be changed with the width of the plate. When the splitter is assembled on the feeding nozzle, the principle is to ensure the smooth flow channel and uniform temperature distribution. When assembling, the shunt block can be fixed on the mouth fan with a pin.

From the ideal condition, it is best that the temperature of the metal flowing out of the outlet is consistent in the whole length of the feed nozzle. In this way, the molten metal can solidify uniformly after contact with the surface of the roll.

In order to avoid non-uniform solidification on the whole cross-section, flow blocking measures are adopted to slow down the flow in the middle and reduce the temperature appropriately. The metal flow at both ends far away from the outlet increases and the temperature increases, so that the metal temperature of the whole cross section is uniform and the metal can flow out of the mouth cavity at the same time.