In order to ensure that the downstream processed ingots or billets meet the strict requirements of high-quality products, such as rigid and flexible packaging materials, aerospace products (extruded parts, plates, plates, forgings), photolithography, automotive condensers and bright trims. In the production process of molten aluminum, insoluble impurities or inclusions are generated during the entire reduction, maintenance, alloying and casting process. Ceramic foam molten aluminum filter device is used to produce high-quality aluminum products. The production of aluminum ingots and billets requires molten aluminum to be relatively free of impurities, such as insoluble solids or immiscible liquid impurities.

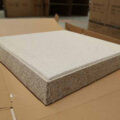

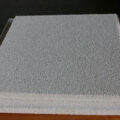

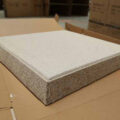

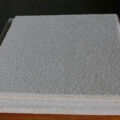

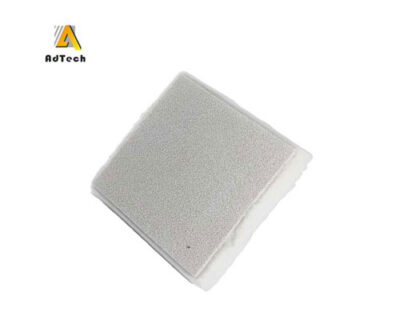

The molten aluminum ceramic filter is a filter medium made of high temperature resistant materials, which will degrade due to chemical reaction with molten aluminum and high temperature corrosion.

The filter media must also maintain structural integrity, such as at high temperatures, and of course must trap or prevent chemical reactions of solids or mechanically prevent fluids and semi-liquids from flowing through them. In the melting, refining, and formation of metals, especially in the casting of molten metal, it is desirable to separate inclusions from the molten metal.

This inclusion of impurities results in the formation of raw materials for the melt from slag, scum and oxides and small fragments of refractory materials in the form of slag, scum and oxide on the surface of the slag. Used to form a cavity, where it is melted to form a metal melt.

If these inclusions are not removed from the molten state of the metal, it may result in a weakening of the points of the final solidified metal body (the final product of the casting operation) and/or a decrease in porosity. Under normal circumstances, the granular refining agent is first added to the molten aluminum, and the slag removal treatment is carried out after sufficient reaction.

Before the molten aluminum filter device is a degassing tank for removing hydrogen from molten aluminum. Finally, after passing through the filtering device, the impurities in the aluminum melt are filtered out.

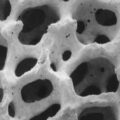

Especially in the case of using a molten aluminum ceramic filter, after long-term use, the pores will be blocked on the surface. Therefore, the filter has a multilayer network structure. The pore size decreases in the flow direction of the liquid aluminum. By setting the particle size of the granular material so that the granular material is continuous or layered in the flow direction of the aluminum melt, the same effect can be achieved, that is, a longer service life can be obtained from the filter.