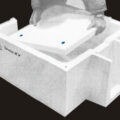

Foam ceramic filter is as molten aluminum filter media used in the casting process, so as to purify the liquid casting alloy and reduce or eliminate various non-metallic inclusions and exhaust problems during the casting process. Casting waste caused by casting defects (such as non-metallic inclusions) accounts for 50%-60% of the total number of waste products.

As various costs increase, damage to the external environment due to the outflow of excess waste can be foreseen. Inclusion defects not only seriously affect the mechanical properties and performance of the casting, but also have a harmful effect on the cutting process and the appearance of the casting.

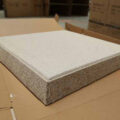

The ceramic foam filter product effectively eliminates the solid inclusions in the molten metal, so it can successfully forge aluminum alloy, manufacture aluminum foil, and perform extrusion processing, so as to obtain high-quality aluminum products. The product has a selection range of 10ppi coarse holes to 70ppi very fine holes, so there will always be a product standard that suits your requirements. Both the ordinary size and the special size required by the customer can meet the requirements.

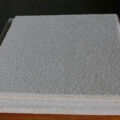

The cast filter has the ability of natural chemical adsorption (affinity) and can adsorb impurities such as fused alumina. Adsorb the impurities in the molten metal (including particles smaller than the pore size) on the inner wall of the hole to improve the filtering effect.

The advanced extrusion production process makes the ceramic filter have a unique square and triangular design, thereby increasing the contact area with the ceramic. Improve the ability of the filter to absorb and trap small impurities, which is better than the non-extrusion filter, and the molten metal flows smoothly, improving the mechanical properties of the casting and extending the service life.

The molten aluminum filter media can reduce the oxidized slag inclusions in the remelted aluminum, purify the aluminum melt, increase the output, reduce the inclusions in the castings, reduce the internal reoxidation defects, and reduce the processing surface defects.

Molten aluminum filter media is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum castings usually use 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.