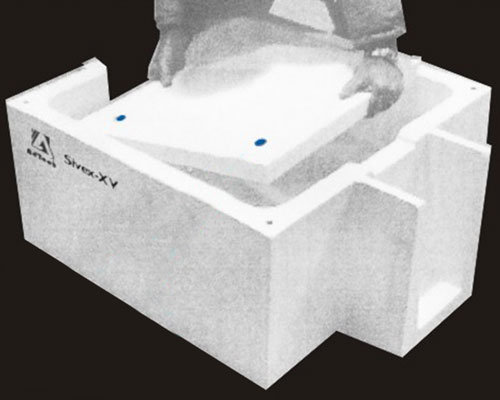

In the molten aluminum filtration process, if the seal between the ceramic foam filter and the CFF filter box is not good, or there is a gap, the molten aluminum will easily flow through the gap without passing through the ceramic foam filter. In this case, the filtering effect will be reduced. The way to improve the sealing effect is to add a layer of Ceramic Fiber Blanket between the CFF filter and the CFF filter box, press the filter tightly, close to the inner wall of the box, and form a good seal between the filter sheet and the box body to improve filtration effect.

Since the temperature of the molten aluminum is low at the beginning, and when the molten aluminum passes through the ceramic filter at the beginning, there are more impurities in the molten aluminum. If the molten aluminum directly enters the filter box, the impurities in it will easily block the ceramic foam filter, resulting in a reduced filtering effect. Therefore, before the molten aluminum enters the filter box, first drain about 100kg of the molten aluminum in the initial stage, and then the molten aluminum enters the filter box to improve the filtering effect. In order to discharge the lower temperature of the molten aluminum at the beginning, the filter system is equipped with two pneumatically operated baffles. One of the baffles is located at the entrance of the filter box, and the other baffle is located at the discharge port of the molten aluminum. In the beginning, the baffle at the entrance of the filter box is closed, the baffle at the discharge port is opened, and the aluminum liquid is discharged from the discharge port. Then the baffle at the discharge port is closed. When the molten aluminum reaches the liquid level specified by the molten aluminum filtration process, the baffle at the entrance of the filter box is opened, and the molten aluminum enters the filter box. After filtering by the ceramic filter, the oxide inclusions are removed.

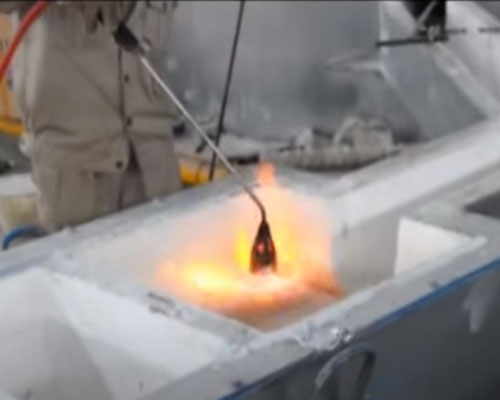

In order to improve the preheating effect of the ceramic filter, the filter system effectively improves the temperature uniformity of the filter by increasing the combustion air flow rate. Prevent the aluminum liquid from blocking the filter due to uneven preheating of the filter, ensure that the aluminum liquid passes through the filter evenly, and improve the filtering effect and the flow of the aluminum liquid. Otherwise, the aluminum liquid will block the filter. On the one hand, the blocked filter hole cannot filter the aluminum liquid, and the filtering effect is reduced. On the other hand, the aluminum liquid cannot pass through the blocked filter hole, which reduces the flow rate of the aluminum liquid through the filter. The flow of molten aluminum cannot meet the flow requirements of the casting process.