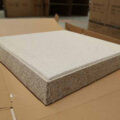

Molten aluminum foam filter can not only effectively remove a large number of heterogeneous impurities in molten aluminum, but also filter out a few microns of small inclusions which can not be removed by traditional technology. Because hydrogen atoms and other harmful ions in liquid aluminum are often adsorbed on inclusions, and inclusions can become the core of bubble formation, so harmful gases in liquid aluminum can be reduced while inclusions are filtered.

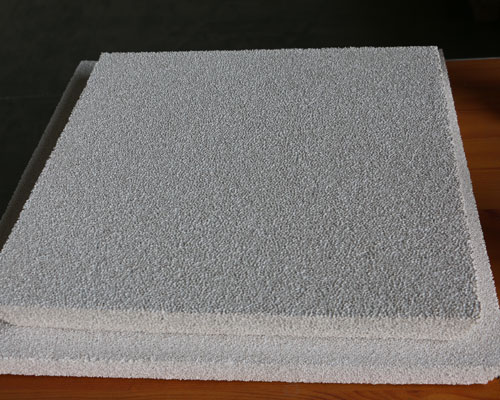

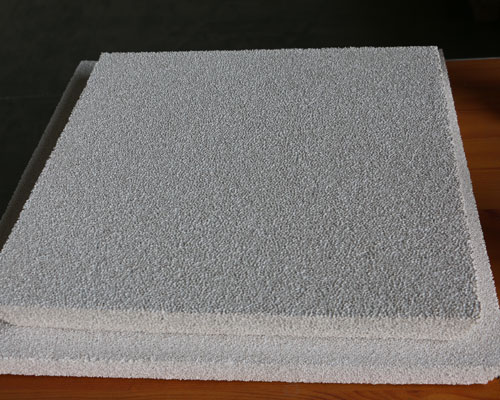

Molten aluminum ceramic foam filter manufacturers will use a more complete set of measures to ensure product stability, to ensure that the final product strength, through-hole rate, geometric size, appearance quality, physical and chemical characteristics are in line with standards.

In production, in order to achieve better filtering effect, the aluminum liquid upstream of the filter must have a certain cleanliness, that is, the aluminum liquid upstream can be treated by traditional gas dehydrogenation or flux.

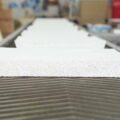

In order to remove more than 30um inclusions, it is recommended to use multi-stage filtration technology and filters with different PPI filter combinations to achieve satisfactory results.

If the above measures are not taken, the filtration and purification of high hydrogen and oxygen content, many non-metallic inclusions and aluminum alloy melt with large size will not only reduce the filtration efficiency, but also block the filter easily, resulting in cost increase and purification effect will not be very good.

After the above measures, the hydrogen content in the alloy melt has been reduced to a very low level, and the size of oxide inclusions in the melt is also small.

Therefore, the use of molten aluminum foam filters can effectively remove fine and dispersed oxide inclusions, thereby improving filtration efficiency and reducing the cost of filtration and purification.

In addition, it is necessary to protect the filtered high-quality molten aluminum from secondary pollution, that is to say, the refractory materials downstream of the filter box should be more stringent, and the surface oxide scale of the downstream molten aluminum must be protected.