Molten metal, especially molten aluminum, often contains solid substances, which can affect the quality of the casting. After the molten metal has solidified, this solid matter appears as an impurity in the casting, resulting in decreased ductility, unsatisfactory surface gloss, and poor anodizing properties.

There are various sources of impurities, for example, from the surface layer of oxidized materials, which will burst and enter the molten metal. In addition, impurities include insoluble impurities, such as carbides, borides, and other compounds or particles falling from the furnace lining.

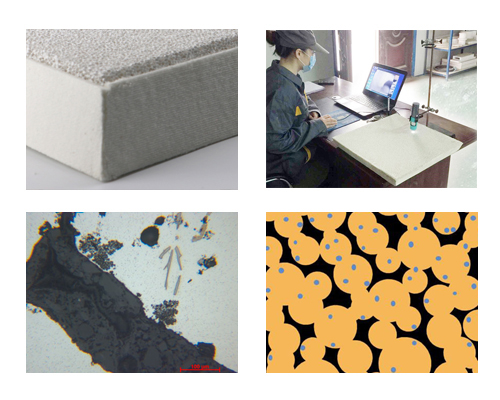

The porous ceramic foam filter is particularly suitable for filtering molten metal because of its good filtering effect, low cost, and convenient use. The filter must first have effective protective measures, so that the filter can be installed on the filtering equipment in a simple way. And it should be fixed well, and it should be easy to take apart and wash.

Ceramic foam filter is based on soft polyurethane foam as the starting material. The basic structure has a regular dodecahedron three-dimensional structure. The internal filtration mechanism of this structure is different from the surface filtration mechanism of other filters. Since the fine-mesh particles are attached to the internal framework for filtration, the flow resistance is small and the particle holding capacity is large, and it is an ideal structure as a filter.

AdTech plate filter box and ceramic foam filter are used together. When in use, the filter is installed in a filter box. The filter box has a filter plate fixing device, the filter plate is in an open shape, and its side is inclined, and the size of the inclination of the filter plate is suitable for the side of the filter assembly. The expanded cotton edges around the filter ensure the corresponding side of the filter box, so the metal is unlikely to seep between the filter and the filter box, reducing the gas generated by the sealing device during the filtering process.