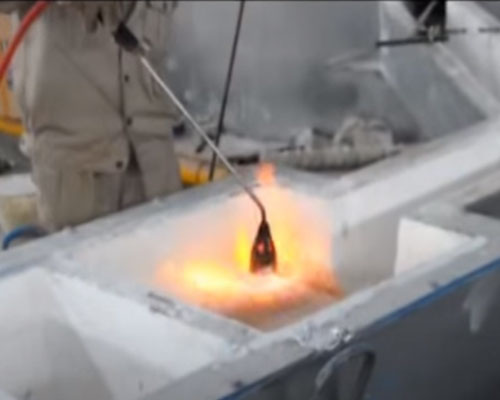

The demand for aluminum products such as aluminum canned drinks and aluminum foil for packaging purposes has increased in recent years. If there are solid impurities in the ingot used to produce aluminum, it will cause pinholes, wire breaks or other similar defects in this aluminum product. Therefore, various attempts have been made to obtain a purified ingot free of solid impurities. Such ingots are produced from the purification of molten fresh metal filtered from the obtained fresh metal to remove solid impurities. Molten metal ceramic foam filters have been recognized as filters with high industrial value.

Ceramic foam filter allows fluid to pass, and a metal layer is formed on the wall surface of its pores, which has good wettability to molten metal. Correspondingly, the formed wall surface has a porous ceramic structure, through which the pores can allow fluid to pass through, can filter molten metal, and the molten metal that can be filtered has high workability and efficiency, and has excellent durability sex.

The porous ceramic structure is used as molten metal ceramic foam filters. It includes pores that allow fluid to pass through. It is characterized in that a metal layer is covered with porous ceramic pores on the wall surface, so that fluid flows through the hole in contact with the metal layer.

Since the metal layer is deposited, the entire wall surface of the pores of the porous ceramic structure through which fluid can pass, when the molten metal flows through the pores, the affinity or wettability with the molten metal is significantly improved. And, accordingly, the porous ceramic structure can be suitably used as a filter to molten metal. Specifically, in the case of using a porous ceramic structure, the filter has an extremely increased affinity for molten metal such as molten aluminum due to the ceramic structure’s affinity with the contact surface or with the wettability of the molten metal compared to the previous situation. The molten metal is in direct contact with the ceramic. As a result, the flow resistance when the molten metal passes through the pores of the filter is greatly reduced, and therefore, the time from when the molten metal enters the filter inlet is greatly reduced.

Even if the initial head pressure is reduced, the raw materials required to start the filtration can be significantly reduced, and the filtration can be started sufficiently. In addition, localized flow eliminates molten metal inside the filter due to improved wettability. Therefore, by increasing the effective passage area of the filter and reducing the flow resistance to the molten metal synergistic effect, the flow head can be reduced while shortening the filtration time and increasing the processing volume. The molten metal content of each filter significantly improves durability. Metals with reduced average pore diameters are used for high-quality metal materials requiring reduced impurity content.