We provide an improved molten metal filtration system, which is mainly used to remove impurities from molten metal. It can collect a certain volume of molten metal, which is sufficient to reduce the heat loss of the molten metal when it flows through the filter system to the casting nozzle, thereby basically preventing the freezing of the casting molten metal.

Molten metal usually contains entrained solids that are harmful to the final cast metal product. These entrained solids appear as inclusions in the final cast product after the molten metal has solidified. These inclusions adversely affect the physical properties and aesthetic appearance of the final cast product.

Ceramic foam materials are particularly suitable for filtering molten metals, including their excellent filtration efficiency, low cost, ease of use and disposable.

The ceramic foam filter can effectively trap the inclusions and reduce the turbulence of the molten metal. The ceramic filter has excellent properties such as precise size, good thermal stability, large specific surface area, acid and alkali resistance. Ceramic foam filters are suitable for a wide range of filtration applications for non-ferrous metal castings.

The ceramic foam filter is installed in the filter box to separate non-metallic inclusions from the molten metal. They are also used to help escape entrained gases from molten metal.

The incoming metal passes through the filter before pouring through the tundish nozzle. During the infusion of the filter, a certain amount of heat in the metal will be lost to the filter system. The heat loss encountered at this stage may be particularly large.

At normal operating metal temperatures, heat loss can continue, which in some cases is sufficient to cause the filtered metal to freeze in the nozzle of the post-filter compartment and stop casting. In many cases, the overall heat loss measured by the temperature probe indicates that there is enough heat in the system for casting; however, the metal in the nozzle has actually cooled enough to freeze and prevent the casting.

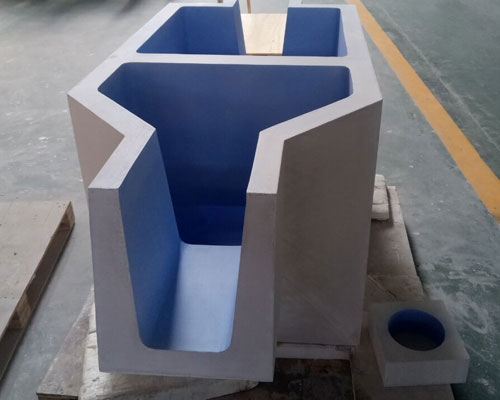

The molten metal filtration system includes a filter chamber having a molten metal inlet, a molten metal outlet, and a ceramic foam filter installed therein. In order to reduce the heat loss of molten metal as it passes through the filter, a barrier is placed immediately downstream of the filter assembly. The dam prevents the initial metal used to filter the filter from directly entering the nozzle. On the contrary, it collects the initial molten metal in a pool, and by providing heated metal on both sides of the filter assembly, the cooling effect caused by the filtering process is greatly reduced.