In-furnace purification has its limitations. For high-end aluminum production, online molten aluminum purification technology outside the furnace is required. The cleanliness of the purification process is also our concern.

Online Degassing Equipment

AdTech on-line degassing equipment has an ultra-long life furnace body using a new type of high-silicon melting material manufacturing technology. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of silicon nitride ceramic manufacturing technology and high additional production. It can meet the production technology of aluminum products with high value and high technical performance requirements.

The on-line degassing equipment is installed between the furnace and the casting machine, and its role is to remove the hydrogen and other residues contained in the molten aluminum and its alloys that affect its quality and mechanical properties. It has dual functions: processing and heating. Mainly used for melt purification in the production of high-precision aluminum products, such as: computer hard drives, color and black and white photocopier drums, micron aluminum foil wool, PS board base for printing, canning materials, and aircraft landing gears.

Online Filtering Equipment

AdTech plate filter equipment has an ultra-long life furnace body and adopts a new high-silicon melting manufacturing technology, which is mainly used for high value-added and high-tech performance requirements for melt purification in the production of aluminum products, replacing the high-cost ceramic tube filter and ordinary filter equipment. It filters inclusions and tiny particles in the molten aluminum through a ceramic foam filter. It is especially suitable for the production of high-purity and high-precision aluminum and aluminum alloys.

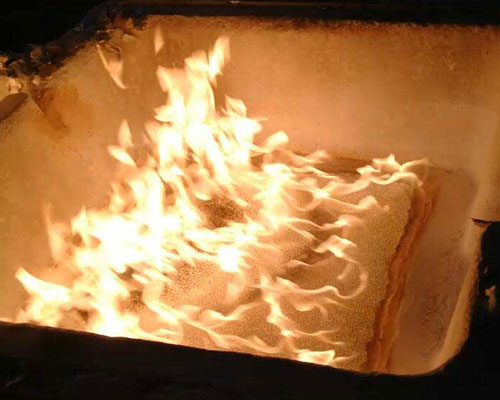

The aluminum melting furnace requires high strength, wear resistance and corrosion resistance of molten aluminum to prevent Fe Si and other harmful metal elements and their oxides from affecting the cleanliness of molten aluminum, especially in the transportation of molten aluminum outside the furnace, it is important to prevent secondary pollution. Because the molten aluminum is processed by the online molten aluminum purification, it is a clean aluminum melt. So we researched and developed:

1. New ceramic refractory material, non-stick aluminum, high strength and long life.

2. Refractory insulation lining to prevent secondary pollution, ensure high degassing rate, deep filtration, and produce high-clean aluminum liquid

3. Improve the high-temperature operation process and develop a series of simple cleaning technologies to prevent contamination by lining, paint, and incomplete cleaning during the transmission process, and improve the cleanliness of the molten metal.