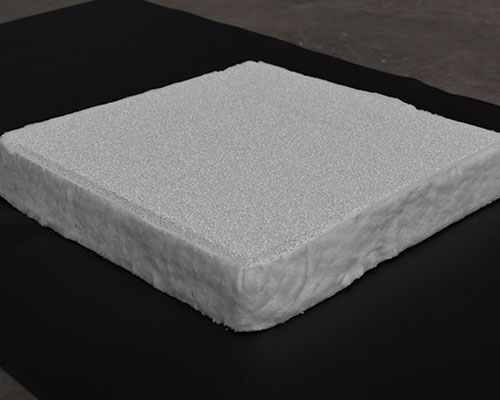

When the ceramic foam filter plate is designed as a disposable item, it is necessary to provide an effective means to seal the filter plate in its proper position in the holder, so as to be easy to assemble, disassemble and clean. AdTech provides a plate filter unit for ceramic foam filter work, it is usually a component of the tank, dump pan or tundish, etc., and should be made of refractory material resistant to molten metal, similar to the refractory material used in standard tank structures.

A gasket-type seal is used to seal the ceramic foam filter plate in place, and the gasket-type seal surrounds the filter plate at the beveled portion of the filter plate at the periphery. The gasket seal ensures that the installation is leak-free and provides an effective separation medium, which is essential for easy disassembly. In addition, since gaskets or sealing devices prevent metal from entering the sealing surface of the holder unit, their use greatly simplifies cleaning and effectively extends the life of the unit by eliminating the problem of metal corrosion. In addition, due to its elasticity, the gasket can provide sufficient friction to hold the filter body in place in the holder or filter chamber without resorting to other types of pressing devices. The elastic sealing device should not wet the specific molten metal, resist its chemical attack, and should be fire-resistant enough to withstand higher operating temperatures.

The plate filter unit can be sealed around its edges with gaskets. The plate filter unit is preferably sealed by an edge seal along the outer peripheral surface of the filter plate, thereby providing a reliable seal, and together with the gasket, provides the mechanical advantage of keeping the filter in place. If simple press-fitting is not enough to fix the filter in place, naturally various mechanical equipment, such as wedges and pressing weights, can be used.

The oblique angle of the filter chamber and the oblique angle of the corresponding filter plate tend to form a reliable seal and hold the filter in place against the buoyancy force acting on it. Naturally, as mentioned above, the gasket or seal should be resistant to the molten metal used. Typical sealing materials used in aluminum processing include refractory fiber-type seals of various compositions, such as expanded cotton edges, fiber paper edges, and fiber cotton edges.