The firing of the porous ceramic filter materials is usually carried out at a temperature higher than the temperature at which the glass phase of the material can be formed and bonding can occur, thus forming the required strength and corrosion resistance characteristics of the final product. Firing is usually carried out in a continuous furnace for 1 hour to 3 hours, and the maximum temperature is maintained for 15 minutes to 1 hour. Lower temperature and shorter duration can improve the economics of production. However, sufficient time and temperature must be provided for the material to obtain the required strength and corrosion resistance.

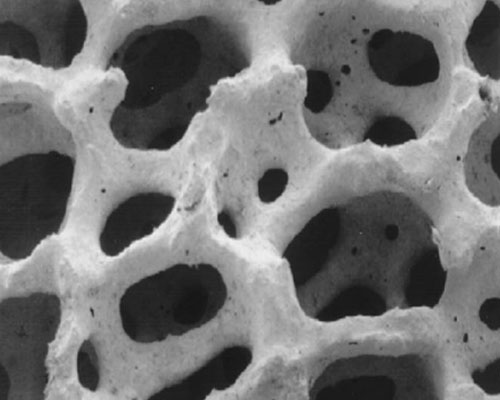

The pore size of the filter medium is mainly determined by the initial pore size of the polymer foam used in the method. In order to effectively filter aluminum alloys, the primary pore size is usually 10 to 70 holes/linear inch. However, each application will require unique pore sizes according to the requirements of the pouring shop or billet machine in a certain application in terms of filtration efficiency and required filtration media permeability.

In the art, the pore size generally refers to the number of holes in a linear dimension, such as the number of holes/inch. A higher PPI value indicates a smaller hole diameter. This is the standard method of recording the aperture.

The density of porous ceramic materials is usually recorded as relative density. The relative density is the ratio of the measured density to the theoretical density, where the theoretical density is the density under the assumption that there are no pores.

Test the entire filter medium. The test time is usually 35 minutes to 120 minutes. Select the test location and use AA6063 or AA6061 or other magnesium-containing aluminum alloys at this location. Use standard filter media gaskets and filter media preheating conditions. The data collected in includes the metal flow rate and pouring conditions, the temperature of the molten metal, and the results of visual observation of the condition of the filter media during the preheating process and immediately after pouring. After pouring, metallurgical analysis of the used filter media was performed to evaluate their ability to withstand corrosive molten aluminum alloy.