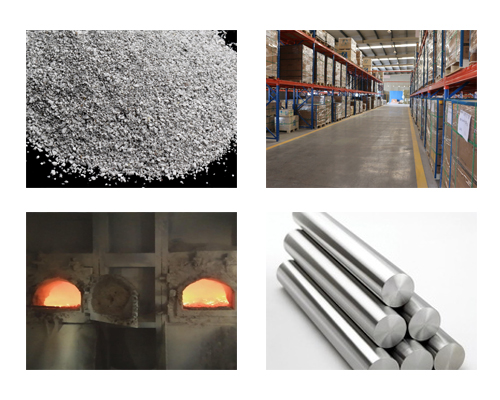

A new type of high-efficiency purification flux replaces the traditional degassing flux, it is used for European aluminum smelter and foundry. The key to its high-efficiency impurity removal is to combine the three processes of aluminum melting, flux filtering, and flux gettering and impurity dissolution, and realize the whole process of melting. The new high-efficiency purifying flux has low melting point, low density and good fluidity.

When used as a filter flux, it is beneficial to form a filter layer faster, further improves the conditions for the diffusion and migration of inclusions to the flux, improves the purification effect, and greatly improves the overall performance of the treated material.

However, the impurity removal mechanism of purification flux is mainly mechanical and physical, and the removal of fine inclusions is not obvious. Ceramic foam filters can be used to further remove fine inclusions in European aluminum.

Since the start of large-scale industrial aluminum production in 1886, the European aluminum industry has been on a steady growth path. Metal aluminum is now the fastest growing metal and the second most used metal in the world.

Initially, the European aluminum industry represented only a limited number of primary aluminum producers. However, a few years later, producers of semi-finished and forged products joined, followed by recycling companies in 2013.

At present, Aluminium Europe represents the entire value chain from primary production to recycling, with more than 85 companies and national associations among its members, and a total of more than 600 factories in Europe (EU, UK, EFTA and Turkey).

Before using the purification flux, European aluminum should be thoroughly dried to remove moisture. This can prevent explosion accidents and improve the refining effect. The refining temperature should be controlled at the upper limit of the casting temperature to improve the refining effect. The amount of flux should be sufficient. For products with higher internal purity requirements, the amount can be larger. The amount used is generally 4-5 kg/t metal; for general products, the amount used is 2-3 kg/t metal.