The presence of gases and various inclusions in the melt causes the ingot to produce pores, non-metallic inclusions, oxide film and other defects, which affect the strength, processing performance, corrosion resistance, anodizing performance and appearance quality of the product. Have a significant impact. Therefore, the purification of aluminum melt is the key to reducing the gas content and non-metallic inclusions of the aluminum melt and improving the quality of processed materials. There are certain differences in the purity requirements of the aluminum melt according to the alloy variety and the use of the product. Generally, the solubility of hydrogen in aluminum melt is required to be below 0.15 ~ 0.2mL/100g, and for some products with special requirements, it should be below 0.1mL/100g.

The presence of hydrogen and inclusions directly or indirectly harms the properties of aluminum and its alloys. Therefore, the purity level of aluminum melt has become the key to the production of high-quality aluminum, which has promoted the continuous development of aluminum purification technology in recent years.

The purification method of aluminum alloy melt in aluminum strip casting can be divided into two basic types: adsorption purification and non-adsorption purification.

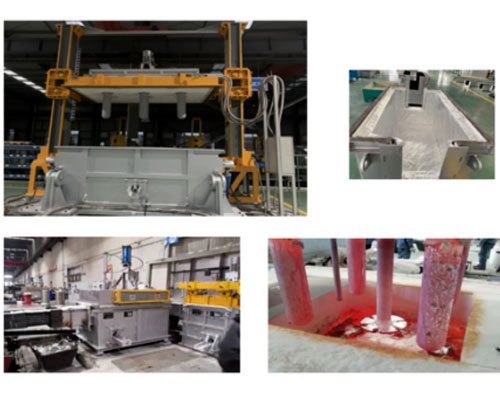

Adsorption purification is through the direct contact of the aluminum melt with the adsorbent (such as various gases, liquids, solid refining fluxes and ceramic foam filter media), so that the adsorbent and the gas in the melt and the solid oxide inclusions are physically and chemically, physically Or mechanical action to achieve the purpose of degassing and impurity removal. Such as rotary degassing method, CFF filtering method, flux refining method, and so on.

Non-adsorption purification refers to changing the equilibrium state of the metal-gas system or the metal-inclusion system through some physical action (such as vacuum, ultrasound, density difference, etc.) without adding adsorbents to the melt, thereby making the gas Or the method of separating solid inclusions from aluminum melt. Such as standing treatment, vacuum treatment, ultrasonic treatment, etc.

Therefore, the purification of metals can be divided into three categories according to their principle of action: adsorption purification, physical transformation (non-adsorption purification), and filtration purification. Melt purification methods can be divided into degassing refining technology, CFF filtering purification technology, and composite purification technology.