The quality of the aluminum melt is very important, it affects the subsequent processing performance and the quality of the final product to a large extent, so the purification of the aluminum melt is an essential step.

There are many reasons for aluminum pollution. On the one hand, when exposed to the atmosphere in the furnace in a molten or semi-molten state during the smelting process, it is easy to oxidize and react with water vapor to absorb argon, and it is easy to form various forms of non-metallic slag such as furnace lining fragments. In terms of chlorides, carbides, etc. in the flux, and coarse intermetallic particles, etc., part of the waste that constitutes the charge brings some non-aluminum impurities during the circulation process. Because the waste comes from the process waste, waste and off-site waste in each process of the factory, the route is different, the composition is complicated, and the quality is poor. The above-mentioned impurities often cause bubbles and inclusions in the casting billet, which seriously affect the purity of the molten metal, thereby further affecting the processing performance, mechanical properties, corrosion resistance and the appearance quality of the product.

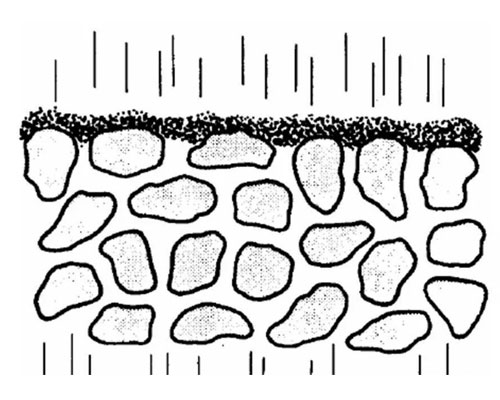

The alumina foam ceramic filter plate can effectively remove various inclusions in the aluminum water with a fineness of micrometers, so that the aluminum water becomes a smooth laminar flow, which is conducive to filling. It has a unique porphyrite-corundum structure, good mechanical strength and chemical stability, and superior aluminum water erosion resistance. Strictly controlled hole size and through hole rate can obtain stable filtering effect. The foam ceramic filter plate is surrounded by a sealing ceramic fiber liner, which helps to seal the filter plate in the filter box and ensures that there is no side flow of molten metal. This product is mainly used in the purification process of aluminum and aluminum alloy production, and also used in various gas-solid, liquid-solid separation media, catalyst carriers, burners, sound absorption and environmental protection.

The ceramic foam filter plates for the purification of aluminum melt has brought huge benefits to the strip foil and its products (such as can blanks, PS printing plates). For manufacturers of aluminum alloy profiles, there are several obvious advantages:

1. Improve extrusion productivity: When using filter plates to purify 6063 alloy extrusion blanks, the extrusion speed increases by about 20%, and the productivity increases by nearly 15%.

2. Extend the life of the mold and reduce the number of mold repairs.

3. Reduce the extrusion force: When the 6063 alloy melt is purified by the filter plate, it is found that the extrusion force is reduced by 3% more than the unfiltered one.

4. Significantly improve the surface quality of aluminum profiles.