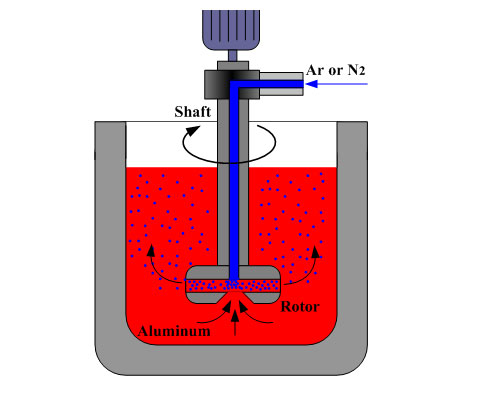

Purified gases such as argon and nitrogen can not only remove gas and alkali, but also can be used to remove impurities. The purge gas is passed into the bottom of the aluminum melt, and the bubbles will come into contact with impurities during the process of floating. And when the impurities and bubbles are wetted with the aluminum melt but not wetted with the aluminum melt, the possibility of them being trapped by the bubbles is greatly increased, and the bubbles can float up into the surface slag layer. This method of removing impurities is called flotation.

The online degassing device is used to remove impurities by flotation.

Studies have shown that it is difficult to remove inclusions below 1um by flotation, and the removal efficiency of inclusions from 1 to 10um is related to the size of the bubbles and the rotation speed of the nozzle. When the inclusions are larger than 6um, they are easily caught by bubbles of 1-10m. Particles above 10um can be removed by the external interception mechanism of the bubble or the inertial collision mechanism. The inclusions of 1-10um can only be removed by the collision mechanism, while the impurities below 1um need to grow up to be removed.

Theoretically, the rotation of the rotor can provide a sufficient growth rate of these impurities so that the impurities that grow to 1-10um can be removed. This method uses rotary spraying to ensure that the contact area between the bubbles and the molten metal is between 2-20m2/kg, and is continuously updated, so that the inclusions can continue to contact the bubbles, thereby continuously removing impurities .

Eliminating the inclusions in the aluminum melt is the key to the purification treatment of the aluminum alloy melt and obtaining high-quality aluminum alloy castings. But to achieve this goal, we must essentially understand the source of inclusions, the mechanism of formation, and the form of existence. Fully consider the various factors in the process of removing inclusions, develop advanced impurity removal technology, and adopt compound purification methods, such as flotation + filtration, so as to achieve the best impurity removal effect and improve product quality.