Rotary metal degassing method is currently the most widely used method of degassing and purifying molten aluminum. AdTech online degassing unit adopts this degassing method for molten aluminum purification.

The principle of the rotary metal degassing method is to pass inert gas or active gas insoluble in the molten aluminum into the molten aluminum, or add chlorine salt (chloride) to react with the molten aluminum to generate a gas, which generates a large number of escaped bubbles in the molten aluminum. Since the partial pressure of hydrogen in the bubble is PH=0, the hydrogen dissolved in the aluminum liquid will continue to enter the bubble. This process is until the partial pressure of hydrogen in the bubble increases to meet the hydrogen concentration in the aluminum liquid (H)=K. PH relationship Only when the balance is reached. After the bubbles rise to the surface, the hydrogen in the bubbles escapes into the atmosphere. Therefore, the continuous generation of bubbles can continuously remove the hydrogen dissolved in the aluminum liquid.

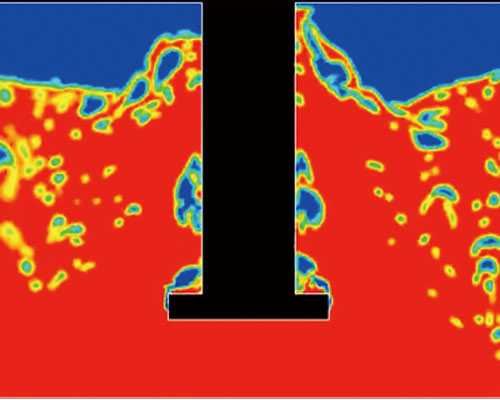

The hydrogen atoms dissolved in the aluminum liquid migrate to the surface of the purified bubble and are adsorbed on the surface of the bubble to form hydrides and enter the hydrogen bubble. Finally, the molten aluminum escapes as the bubbles rise to complete the degassing and purification of the molten aluminum. This is a process in which hydrogen diffuses in the liquid phase and is adsorbed by bubbles.

The rotary metal degassing method can better meet the degassing dynamics conditions of the bubble floatation method. The purified gas is introduced from the gap between the shaft and the sleeve, and is broken when flowing through the rotating nozzle blades at the lower part and ejected at high speed. Then, the molten aluminum flowing with the rotation rises to the liquid level.

Our rotary degassing unit can meet the production of aluminum products with high technical performance requirements, it is widely used in aluminum foundry. The main components of degassing unit include a mechanical drive, box lid, rotor, and heater. Aluminum degassing machine is between the furnace and the casting machine, the main function is removing hydrogen and other residues. Otherwise, these gases will affect the quality and mechanical properties of aluminum and its alloys.