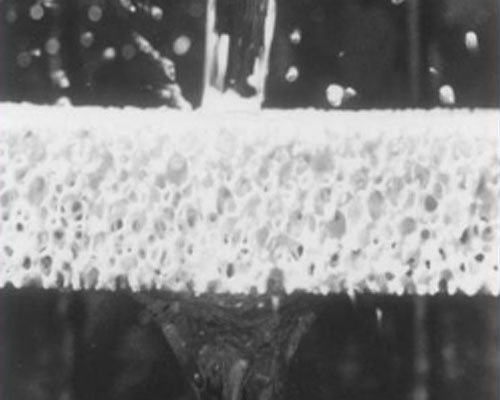

Rusal aluminum casting filter mainly adopts ceramic foam material as filter medium. The ceramic foam filter has a unique three-dimensional connected curved pore network skeleton structure, and the open porosity is 80%-90%.

Rusal aluminum casting filter has four filtration and purification mechanisms, namely: screening-filter cake-deep bed filtration mechanism, floating separation mechanism, deep filtration (physical adsorption), and rectification mechanism.

Rusal aluminum casting filter can efficiently filter out large inclusions in molten metal and most of the tiny suspended inclusions as small as tens of microns. Compared with the fire-resistant fiber filter and the straight-hole honeycomb ceramic filter, the ceramic foam filter has the characteristics of high refractoriness, high strength, good filtering effect, and high filtering efficiency.

The Siberia area in Russia has a vast area, abundant hydropower resources, low electricity prices, low aluminum ingot production costs, and obvious advantages in the development of electrolytic aluminum. Russia has developed a number of large-scale electrolytic aluminum plants in this area. In order to improve electrolytic aluminum production technology, solve raw material supply, further expand production capacity, and enhance market competitiveness, Rusal has rapidly developed into an aluminum giant with important international influence through integration and mergers. Rusal ingots are mainly exported to the United States, Japan, and Europe, accounting for 19% and 18% of the total aluminum ingot imports of the first two countries respectively.

Foam ceramic aluminum liquid filtration and purification method and device are suitable for all aluminum production departments, including sheets, strips, foils, bars, pipes, wires, extrusions, forgings, primary aluminum ingots, recycled ingots and continuous castings, manufacturing rolling bearings, etc.

Ceramic foam filters can improve the ingot quality, reduce inclusion defects, all of which contribute to bottom-line profit. 30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the Rusal aluminum casting industry. Foam Ceramic Filter effectively removes various non-metallic inclusions in the aluminum melt during the aluminum melting and casting process, improves the purity of aluminum rods and ingots, and helps to improve product quality and reduce costs in the melting and casting workshop.