Temperature Control in Aluminum Melting is important for aluminum casting foundry. The melting temperature is too low, which is not conducive to the dissolution of alloy elements and the discharge of gas and inclusions during refining. This increases the tendency to form segregation, cold separation, and under-casting, and the castings cannot be properly compensated due to insufficient riser heat. The melting temperature of all aluminum alloys should reach at least 705 degrees and should be stirred.

Excessive melting temperature wastes energy. Moreover, the higher the temperature, the more hydrogen absorbed, the coarser the crystal grains, the more serious the oxidation of aluminum, and the more serious the burning of some alloying elements. This leads to the decline of the mechanical properties of the castings, the deterioration of the casting properties and mechanical properties, the weakening of the effect of modification treatment, and the reduction of the airtightness of the castings.

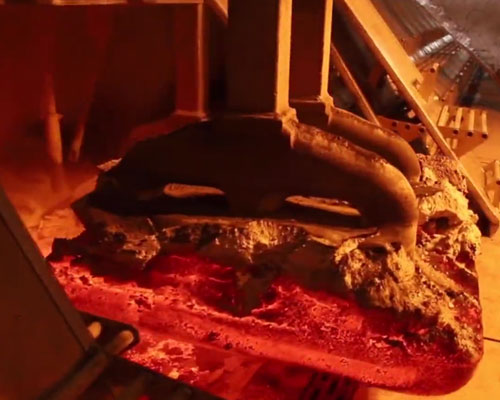

Practice has proved that the aluminum water is quickly heated to a higher temperature and agitated reasonably to promote the dissolution of all alloying elements, especially refractory metal elements. After removing the scum, the pouring temperature is lowered. In this way, the degree of segregation is minimal, and the amount of dissolved hydrogen is also less, which is good for obtaining uniform and dense castings with high mechanical properties. Because the temperature of molten aluminum is difficult to judge with the naked eye, no matter what type of melting furnace is used, a temperature measuring instrument should be used to control the temperature. The temperature measuring instrument should be checked and repaired regularly. The thermowell should be cleaned regularly with a steel wire brush and coated with protective paint to ensure the accuracy of the temperature measurement results and prolong the service life.

Temperature Control in Aluminum Melting

In order to reduce the aspiration of molten aluminum, the dissolution of oxides and iron, the residence time of molten aluminum in the furnace should be shortened as much as possible and smelted quickly. Aluminum usually uses the refining flux to remove the gas and includes in molten aluminum. From the beginning of melting to the completion of pouring, sand casting does not exceed 4 hours, metal mold casting does not exceed 6 hours, and die casting does not exceed 8 hours.

In order to speed up the smelting process, the reheating material and aluminum-silicon master alloy with medium lumpiness and low melting point should be added first to form a molten pool as soon as possible at the bottom of the crucible. Then add a larger recycle material and pure aluminum ingots, so that they can be slowly immersed in the gradually expanding molten pool and quickly melted. After the charge is completely melted, add alloy and stir to accelerate the melting. Finally, the temperature is lowered to reduce burning loss.