The use foam ceramic filter can be placed in various parts of the casting system, either horizontally or vertically. The size and shape of the ceramic filter should be selected according to the characteristics of the casting and the production conditions. Generally speaking, the closer the filter is placed to the gate, the better the filtering effect.

Select the appropriate filter according to the type of molten metal, the weight of the casting and the specific quality requirements. Generally speaking, the user has higher requirements for casting defects and special requirements for processing performance, and castings that require processing on all inner and outer surfaces of the casting should be used Filter sheet.

Design a suitable filter section: Due to the blocking effect of the filter and the gradual blockage of part of the mesh, the cross-sectional area of the filter is required to be larger than the normal sprue cross-section, generally 3 to 4.5 times the sprue area.

Use Foam Ceramic Filter Effect

- After using the ceramic foam filter, the casting inclusions are greatly reduced.

- The processing performance of castings has been significantly improved. When the filter is not used for the exhaust pipe casting, the tool can only process 40 castings on average. After the filter is used, the tool can process 50 exhaust pipes on average, and the tool life is significantly improved.

- Due to the reduction in the scrap rate, many companies can reduce the loss of raw materials, castings, labor costs, and tools caused by scrap by up to millions of yuan each year.

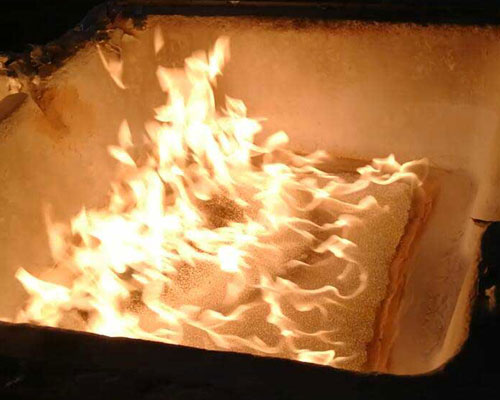

The use of ceramic foam filters in the production of automobile castings has a convenient casting process and low cost. It is an effective, feasible, and simple method to improve the quality of castings. The ceramic foam filter has only minimal resistance to molten metal, and has a strong filtering effect on impurities in the molten metal.

The foam ceramic filter is used to filter molten metal impurities at a low price and high quality, which can improve the quality of the casting, reduce the rejection rate, obtain a smoother casting surface, and improve the mechanical properties of the casting.

The ceramic foam filter can effectively remove various inclusion defects, improve the processing performance of the castings, and thus obtain more economic benefits for the enterprise, which has been proved in the use of many foundries.