Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the ceramic foam filter.

The CFF filter box should be thoroughly cleaned before the use of molten aluminum filter, so as to prevent the residues left from being immersed in the aluminum liquid. The size of the ceramic foam filter plate should be matched with the filter box, and the matching gap between the two should be as small as possible. After repeated use of molten aluminum filter, the filter plate will be distorted, the force of the filter plate is uneven, and the filter plate is often suddenly broken during the filtration process. Therefore, when the filter box is deformed, it should be replaced immediately.

Use of Molten Aluminum Filter

After the filter box is cleaned, coat a layer of BN refractory material on the inner surface of the CFF filter box, and then gently place the foam ceramic filter plate on it.

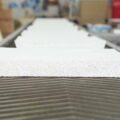

Correct preheating is an important part of the use of ceramic foam filter plates. Incorrect preheating method often leads to the following problems:

- crack preheating occurs;

- the filter plate cannot be started (aluminum liquid cannot pass through);

- the pressure head is too high; the filter plate floats.

The commonly used preheating equipment is a natural gas flame spray gun. The ratio of natural gas to air is adjustable. After igniting the musket, reduce the fire to a minimum, put the musket at the exit of the filter box, and do not put the gun head in. After about a minute, the flame turned blue. After heating for about ten minutes, the filter plate will gradually turn fiery red, indicating that the preheating is better.

After casting begins, you should pay attention to the changes in the aluminum hydraulic head. Under normal circumstances, the initial pressure head is 75~150 cm. When the molten aluminum passes through, the pressure head will drop below 25 cm, and then the pressure head will slowly rise again.