Zirconium Oxide Ceramic also called zirconia ceramics. Zirconia Ceramic has high melting and boiling points, high hardness, insulators at room temperature, and electrical conductivity at high temperatures. Zirconium oxide ceramic is a new type of ceramics with outstanding physical and chemical properties. At present, zirconia ceramic properties are only slightly inferior to alumina among various metal oxide ceramics. In terms of structural ceramics, zirconium oxide ceramics are widely used in the field of structural ceramics due to their high toughness, high bending strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coefficient close to steel.

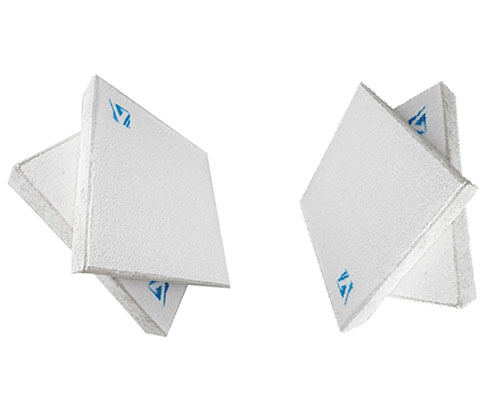

Zirconia ceramic foam filter has a three-dimensional porous structure, high-temperature resistance (up to 1700C), high strength, can filter a few microns of slag in high-temperature molten steel, make the surface of steel castings smoother, reduce machining losses and reduce production cost, improve labor productivity. It can also make the flow rate of the molten metal slow and orderly, so that the molten steel can effectively and fully fill the mold, make the internal structure of the steel casting more evenly distributed, significantly improve the comprehensive mechanical properties of the steel casting, and improve the quality of the casting.

In the production of aluminum alloy, due to the limitation of the process, the small suspended non-metallic impurities in the melt cannot be completely removed, resulting in the excessively high rate of casting waste. Therefore, the filtration and purification process has emerged to make the non-metallic impurities in the molten metal effective Of the filter. The ceramic foam filter has a unique three-dimensional connected curved pore network skeleton structure. Its main characteristics are high open porosity, tortuous channels, and large surface area. This structure can fully contact the molten metal, large debris and most of 10um. The above impurities have increased the filtration efficiency from the previous 50%-60% to 72%-97%.

Function of Zirconia Ceramic Foam Filter

Removal of impurities and slag: Purify the molten metal while degassing.

After adjusting the turbulent flow and filtering, the viscosity of the molten metal is reduced, and the fluidity of the aluminum alloy is increased by 5%.

Improve the filling ability of molten metal.

The flow of molten metal before filtration is turbulent, and after filtration, it becomes laminar flow (the flow channel of the foam ceramic filter is twisted and turned), which reduces entrainment and secondary slagging.

As the filtration progresses, the filtration mechanism changes from sieving, filter cake to deep bed filtration, and the purity of the filtered molten metal is getting higher and higher.